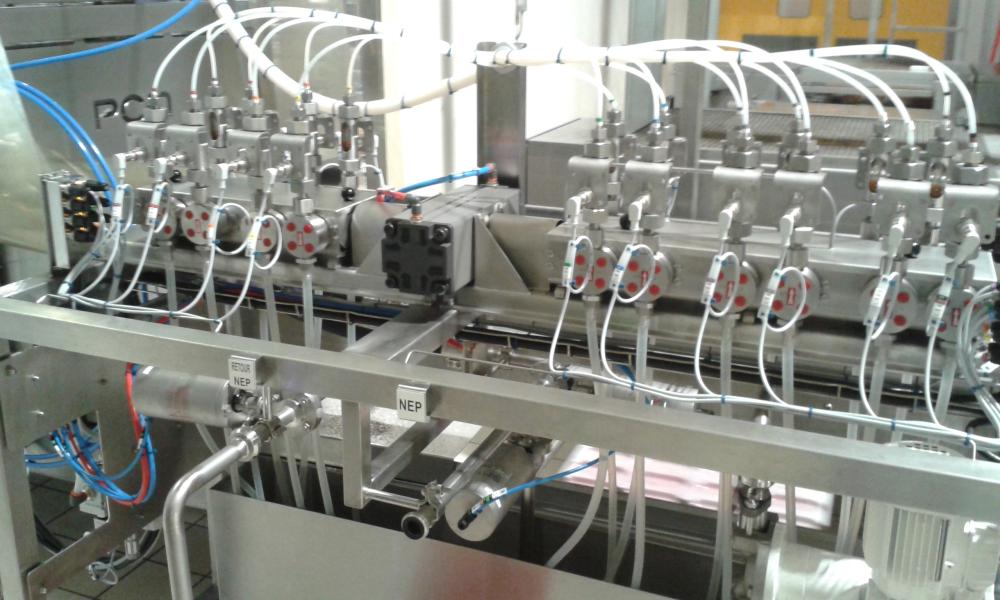

PCM systems for industrial baking, pastry making, and viennoiserie production

Bakery, Viennese Pastry (BVP) covers a wide spectrum of products, whether they are cooked, frozen, pre-cooked or raw. PCM supports this industry with high-performance dosing, dispensing and injection solutions, combining precision, hygiene and adaptability.

- Fresh baked goods

- Frozen baked products

- Frozen pre-cooked products

- Frozen raw products

Typical applications of our PCM solutions in baked goods industries

Removal / Topping

- Chocolate continuous topping on puff pastry (e.g. pains au chocolat)

- Icing sugar, jams, creams, fillings on biscuits, pancakes or pastries

- Chocolate or custard decorations

- Fruit on clafoutis

Injection / Stuffing

- Chocolate, caramel, honey or jam in buns or donuts

- Flavourings or creams in buns

- Choux pastry filling in profiteroles

Dosing & Transfer

- Dosing of liquid products (eggs, milk, oils, flavourings) before kneading

- Transfer of pulp or high-viscosity products

- Mixing liquid/paste preparations

Injection of alcoholic flavourings into milk buns

Know more about PCM Additive station

Manufacture of filled waffles

Know more about PCM DosydrumWhy choose PCM for your bakery applications?

- Reliability and regularity of production

- Product versatility : one machine for multiple recipes

- Guaranteed external cleanliness after injection

- Food Hygiene Compliance

Are you a BVP player? Let's discuss your production line