Micro dosing solutions for liquid ingredients

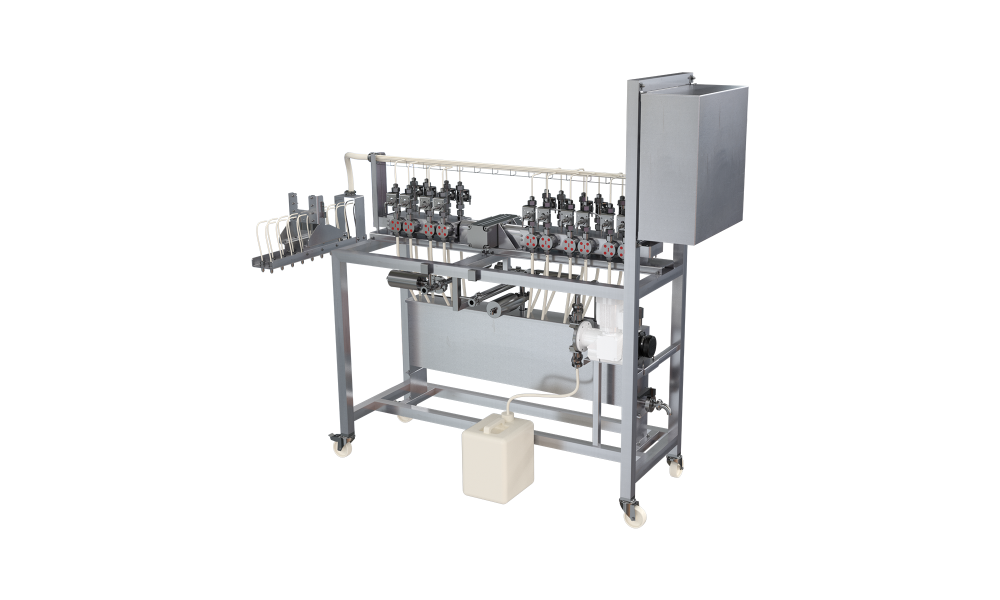

PCM Additivefill

Micro-dosing of flavourings, vitamins, acidity regulators or colourings on the packaging line requires a compact, precise and perfectly orchestrated system. PCM Additivefill™ is a modular solution, fully synchronized to your throughput and filling machine.

The PCM Additivefill skid is designed for dosing and filling homogeneous liquid products in any type of container. This filling system is particularly popular with the dairy industry for dosing small doses of rennet at the bottom of the pot in yoghurts.

Why choose the PCM Additivefill solution?

- Adaptable to all types of containers and customer processes

- Two technologies to choose from : Dosys™ or MDS (depending on precision, throughput, number of flavors, etc.)

- Multi-product dosing possible in the same cycle

- Compact and mobile, easy to integrate into new or existing lines

- Compatible with various containers : jars, bottles

- Reliable and repeatable thanks to Dosys™ technology

- Hygienic : cleanable components in place, sanitary design

Technical features

Precise and controlled dosing

- Dosys™ pump technology (0.1 to 40 cc depending on model) or MDS MPP multi-head pump (0.8 to 1.4 cc) adapted to the requirements of precision, speed, regularity and number of products to be dosed simultaneously

Process synchronization

- Dosing perfectly synchronized with the packaging machine (dosing top or container presence detection).

- Unified cycle for multiple heads: e.g. 2 feeders for rennet, 20 heads for flavouring.

- Flexibility of adjustment: Automatic dose adjustment according to the recipe (Dosys™ servo pumps).

- Manual Fine : Stroke Adjustment Membrane (MDS MPP).

Hygiene guaranteed without dismantling

- Integrated CIP : cleaning in place, without dismantling the circuit.

- Closed circuit with recovery of MDS MPP cleaning solution).

- Specific cleaning sleeve for suction rod ( Dosys™ pumps).

Simple and direct feeding

- Direct suction in the canisters on the chassis, without intermediate transfer.

- Automatic low-level detection of product in the canister

Compact, embeddable design

- Mobile and compact unit, easily integrated into any existing line.

- Integrated control cabinet (console or electro-pneumatic, depending on version).

INDUSTRY

INDUSTRY

BENEFITS

APPLICATION

TO KNOW MORE

Dairy

Dairy

Accuracy, throughput, cleanliness of dosing

Rennet at the bottom of a jar for rennet dessert

Dairy

Dairy

Accuracy, throughput, cleanliness of dosing

Concentrated aromas at the bottom of thermoformed jars

Ready Meals & Sauces

Ready Meals & Sauces

Accuracy, throughput, detection of the presence of product under the nozzle

Flavour enhancer spray on meat-based preparation

Are you looking for a solution without compromising on speed or hygiene?

With PCM Additivefill™, you benefit from a modular, scalable system that is fully synchronized with your process.

To design the ideal configuration for your additives, format and production rate.

FAQ – PCM Additivefill