Topping: a finish without compromise

Finalize your recipes with precision, hygiene and elegance

As the last step in culinary preparation, the topping plays a decisive role in the appearance, texture and deliciousness of the finished product. It sublimates your creations while respecting their integrity.

At PCM, we help you master this critical step with ultra-precise, hygienic dispensing systems that can be adapted to any type of product or container.

Why choose PCM for topping?

- Wide range of dispensing nozzles, suitable for all textures (viscous, sticky, stringy, etc.),

- Precise management of doses and coverage (partial or total),

- Respect for presentation : no dripping, no bubbles, clean rendering,

- Hygienic and cleanable-in-place (CIP) design,

- Full customization : number of tracks, synchronous dispensing, flow control, temperature maintenance.

INDUSTRY

INDUSTRY

BENEFITS

APPLICATION

TO KNOW MORE

Ready Meals & Sauces

Ready Meals & Sauces

Accuracy, cleanliness of dosage, cleanability

Mayonnaise on sandwiches / Snacking

Ready Meals & Sauces

Ready Meals & Sauces

Precision, Respect for Pieces,

Bolognese sauce with meatballs

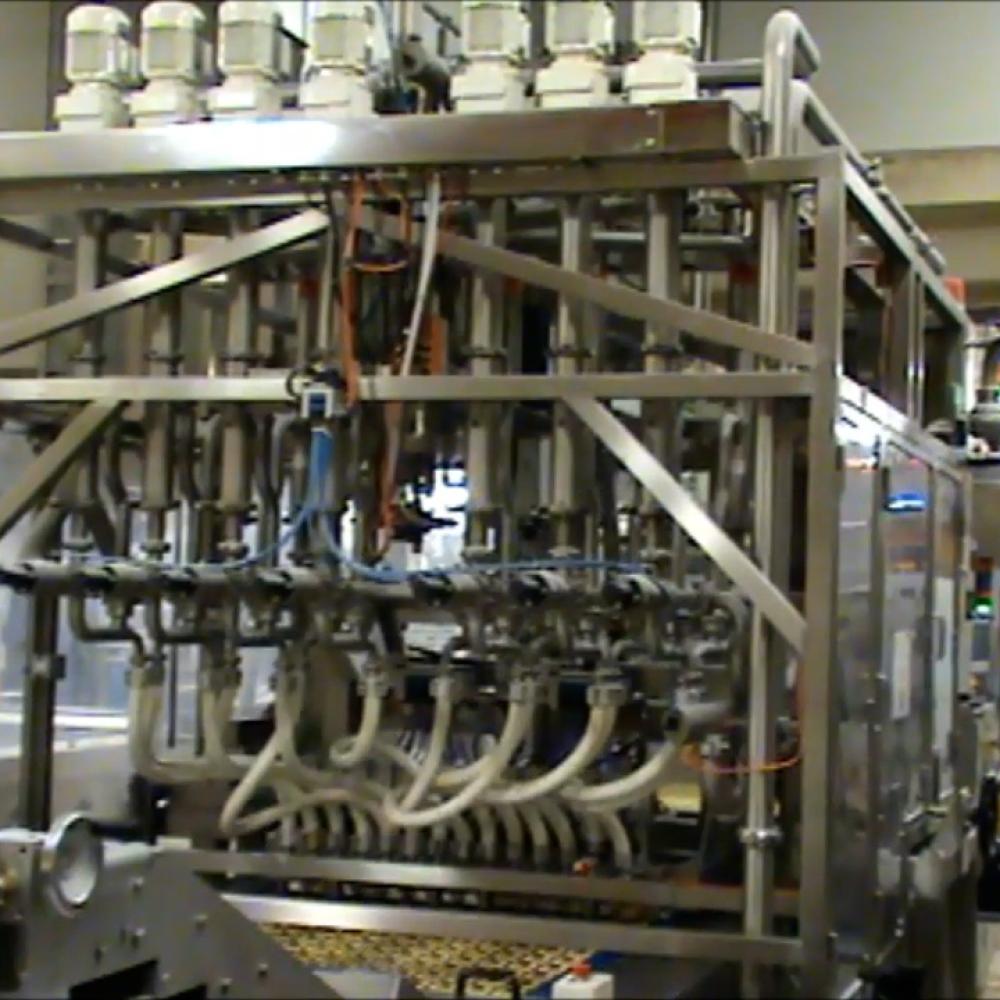

What is PCM Solution for Topping?

Enhance your products with a perfect application

With PCM, topping becomes a differentiating force in your recipes. Thanks to our expertise in hygienic systems, we help you combine aesthetics, efficiency and safety on your production lines.

In order to build together the topping solution that will enhance your products,

FAQ – Topping