Stuffing: precision and creativity

Sublimating your preparations... with control and flexibility

At PCM, stuffing is more than just injecting an ingredient — it’s an opportunity to differentiate your product and enhance its texture, taste, and appeal.

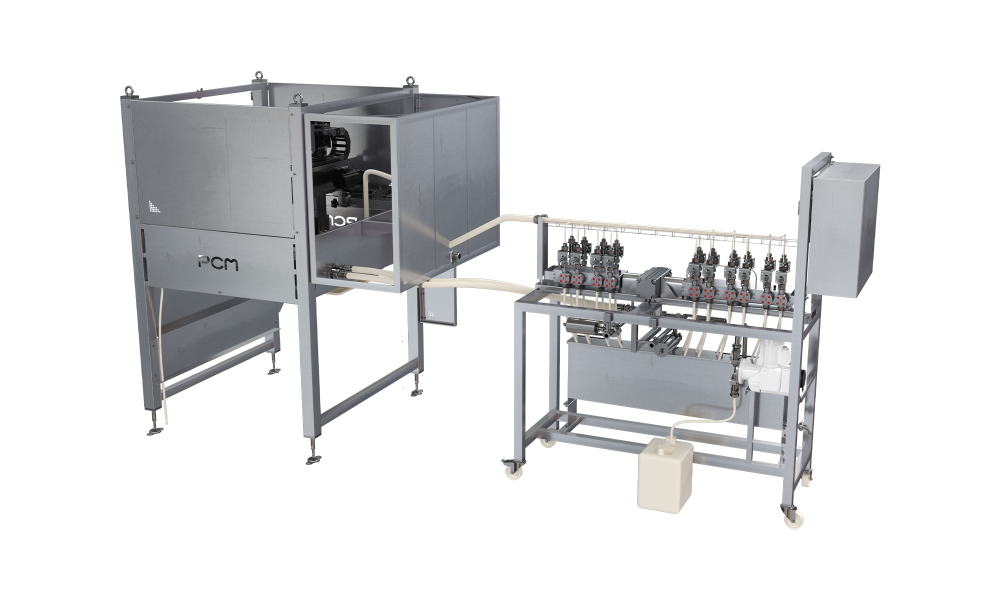

That’s why we’ve developed a range of hygienic, reliable, and flexible solutions to support bakery, dairy, and snacking manufacturers in meeting their production needs.

Why choose PCM for stuffing?

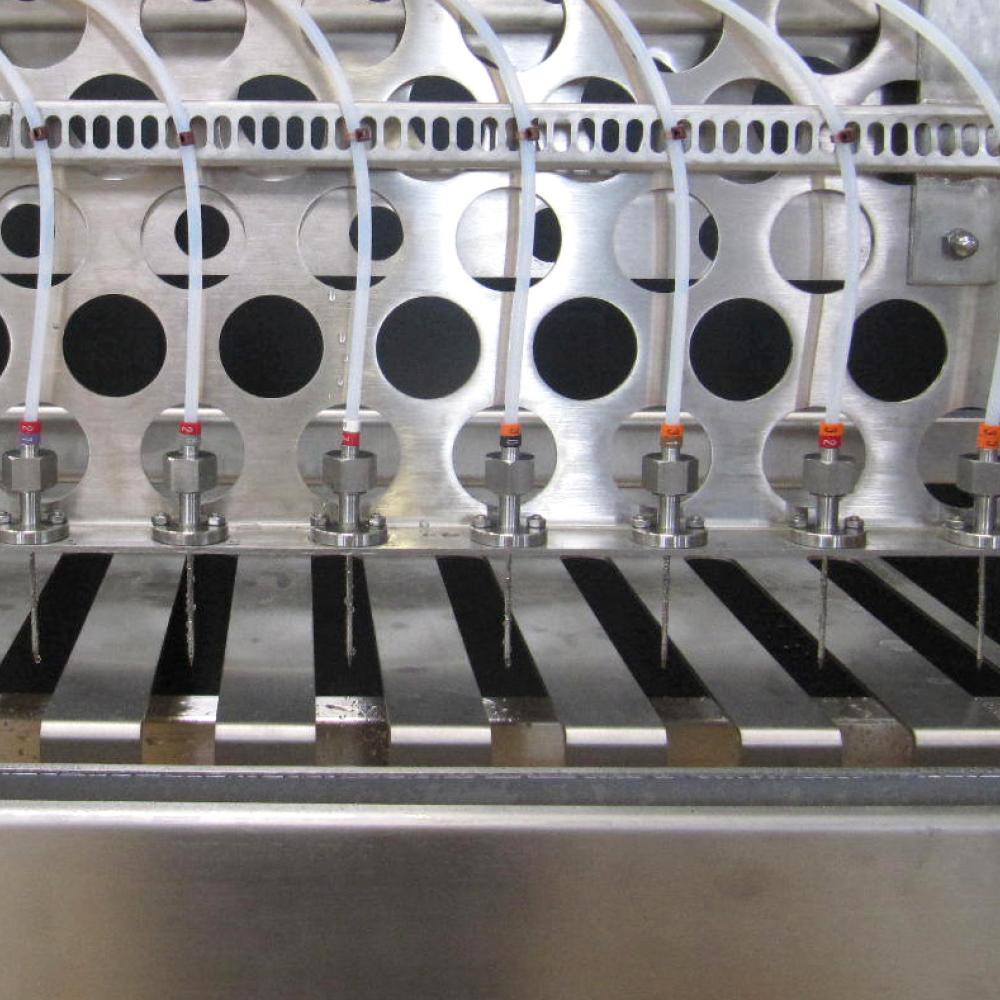

- Ultra-precise dosing, even at high speeds

- Respect for the texture of the ingredients (creams, jams, flavourings, etc.)

- Heterogeneous or continuous product compatibility

- Hygiene guaranteed, with fully cleanable-in-place (CIP) systems

- Customization: number of heads, type of tapping, temperature maintenance, integration on existing conveyor, etc.

Your constraints, our solutions

Our systems adapt to the most demanding environments:

- Up to 35000 products/hour

- Up to 90 simultaneous tapping heads

- Automatic product detection on conveyor

- Container change without production stoppage

- Maintaining product Temperature up to the stage of stuffing

- Impeccable hygiene

Two technologies adapted to your recipes

Boost your line with a tailor-made solution

Thanks to its expertise in pumps and food systems, PCM supports you in the development of a stuffing line adapted to your constraints, your production rate and your creative ambitions.

To build together the solution that will make your products benchmarks in their market,

FAQs - Stuffing