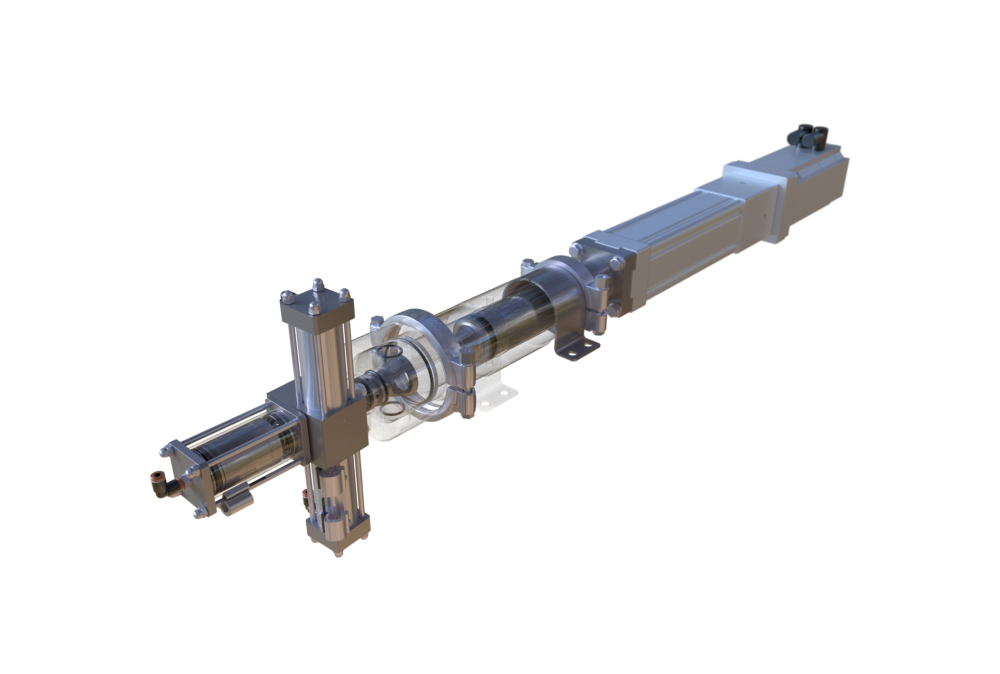

High Precision Piston Metering Pump

PCM Dosys™

The PCM Dosys™ pump is a unique solution for hygienic dosing of even the most delicate food, cosmetics or pharmaceutical products.

Thanks to its volumetric piston system and its full-bore controlled valve dosing head, it allows ultra-precise, reproducible and respectful dosing of textures and pieces.

The Dosys™ PCM pump consists of a patented rotary cylinder and a piston driven by a brushless electric linear mechanism.

This efficient and precise technology, at the heart of all our dosing and filling systems, can be integrated into all your processes, and can advantageously replace systems that are costly in terms of product loss.

The Dosys™ pump synchronizes directly to the filling and packaging machine. The piston, driven by a brushless servo motor, and the patented rotary valve ensure precise dosing of the ingredients. This technology also ensures the dosing of fluids with solid ingredients without deteriorating their structure.

Why choose PCM Dosys™ technology?

- Perfect accuracy of desired doses (0.5% repeatability)

- Accepts fluids with particles (up to 48mm)

- The absence of stirring in the pump body prevents any emulsion, aeration or shearing of the pumped fluid

- CIP and steam sterilization capability

Technical characteristics

The PCM Dosys™ pump is the only pump capable of dosing fluids with large particles while maintaining high accuracy at high flow rates.

Key Advantages

- Preserves ingredient texture – handles pieces up to 48 mm

- Exceptional dosing accuracy and repeatability – ±0.5%

- Minimal ingredient loss

- Self-priming capability

- Highly versatile and flexible

- No emulsion, aeration, or shear

- Complies with CE 1935/2004, FDA, and 3A food standards

- CIP/SIP-ready – cleaning and sterilization in place

- Proven reliability – trusted in food systems worldwide

Performance Specifications

- Dose range: 0.05 cc to 2,654 cc per dose

- Speed:

– Up to 80 doses/min for 1 cc doses

– Up to 20 doses/min for 1,000 cc doses - Pressure capability:

– Up to 20 bar for doses from 0.05 to 180 cc

– Up to 4 bar for doses above 636 cc

DOSED PRODUCT

DOSED PRODUCT

SPECIFICITY

CONTEXT

RESULTS

Jam with pieces

Jam with pieces

Respect for the pieces

Injection at the heart of the product

Homogeneous dispensing

Custard

Custard

Shear-sensitive texture

Topping on pastry

Clean dosing, without destructuring

Syrup or flavouring

Syrup or flavouring

Small volume (1–3 ml)

Flavouring in pots or rows

Dosing accuracy

Spread

Spread

Sticky and stringy product

Pot filling

Clean dosing without dripping

Cheese sauce

Cheese sauce

Stringy product with inclusions and markings

Ready meals in trays

Clean dosing without dripping

Do you need a precise, hygienic dosing solution adapted to all your food and cosmetic products?

The PCM Dosys™ pump can be adapted to your line, your recipes and your speed or hygiene requirements.

FAQ – PCM Dosys™